Double Edge Razor Blade: The Difference Between Stainless Steel, Swedish Stainless Steel, and Carbon Steel

When it comes to shaving, choosing the right razor blade material can make a significant difference in user’s shaving experience. Double edge razor blades are a popular choice among wet shavers due to their versatility and close shaving capabilities. In this article, we will explore the differences between four common materials used for double edge razor blades: 4cr13 stainless steel, 6cr13 stainless steel, Swedish stainless steel, and carbon steel.

Before diving into the specifics of different materials, it’s essential to understand the significance of material selection when it comes to double edge razor blades. The material used can affect various aspects, including the blade’s durability, sharpness, and overall performance.

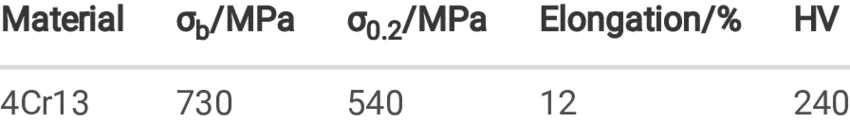

1. 4cr13 Stainless Steel

4cr13 stainless steel is a popular material choice for double edge razor blades. It is a type of martensitic stainless steel known for its corrosion resistance and toughness. The “4cr13” designation refers to the composition of the steel, which includes 4% chromium.

Properties and Characteristics

- Good corrosion resistance

- Moderate hardness and edge retention

- Easy to sharpen

- Affordable

Pros and Cons

Pros:

- Corrosion-resistant, making it suitable for wet shaving environments

- Offers a balance between sharpness and durability

- Budget-friendly option

Cons:

- Not as durable as some other materials

- May require more frequent blade changes

2. 6cr13 Stainless Steel

Similar to 4cr13 stainless steel, 6cr13 stainless steel is also a martensitic stainless steel with increased chromium content. The “6cr13” designation indicates 6% chromium in its composition.

Properties and Characteristics

- Improved corrosion resistance compared to 4cr13

- Good hardness and edge retention

- Relatively easy to sharpen

- Cost-effective

Pros and Cons

Pros:

- Better corrosion resistance than 4cr13 stainless steel

- Provides a good balance between sharpness and longevity

- Affordable option for wet shavers

Cons:

- Not as durable as higher-grade stainless steels

- Regular blade changes may be required for optimal performance

3. Swedish Stainless Steel

Double Edge Blade Testing Report

Swedish stainless steel is renowned for its exceptional quality and is often used in premium double edge razor blades. It is known for its high corrosion resistance, hardness, and edge retention properties.

Properties and Characteristics

- Excellent corrosion resistance

- High hardness and edge retention

- Requires more effort to sharpen

- Relatively expensive

Pros and Cons

Pros:

- Superior corrosion resistance, suitable for prolonged exposure to water

- Provides excellent sharpness and long-lasting performance

- Preferred choice for wet shaving enthusiasts seeking premium quality

Cons:

- Higher cost compared to other materials

- Requires skill and patience for sharpening

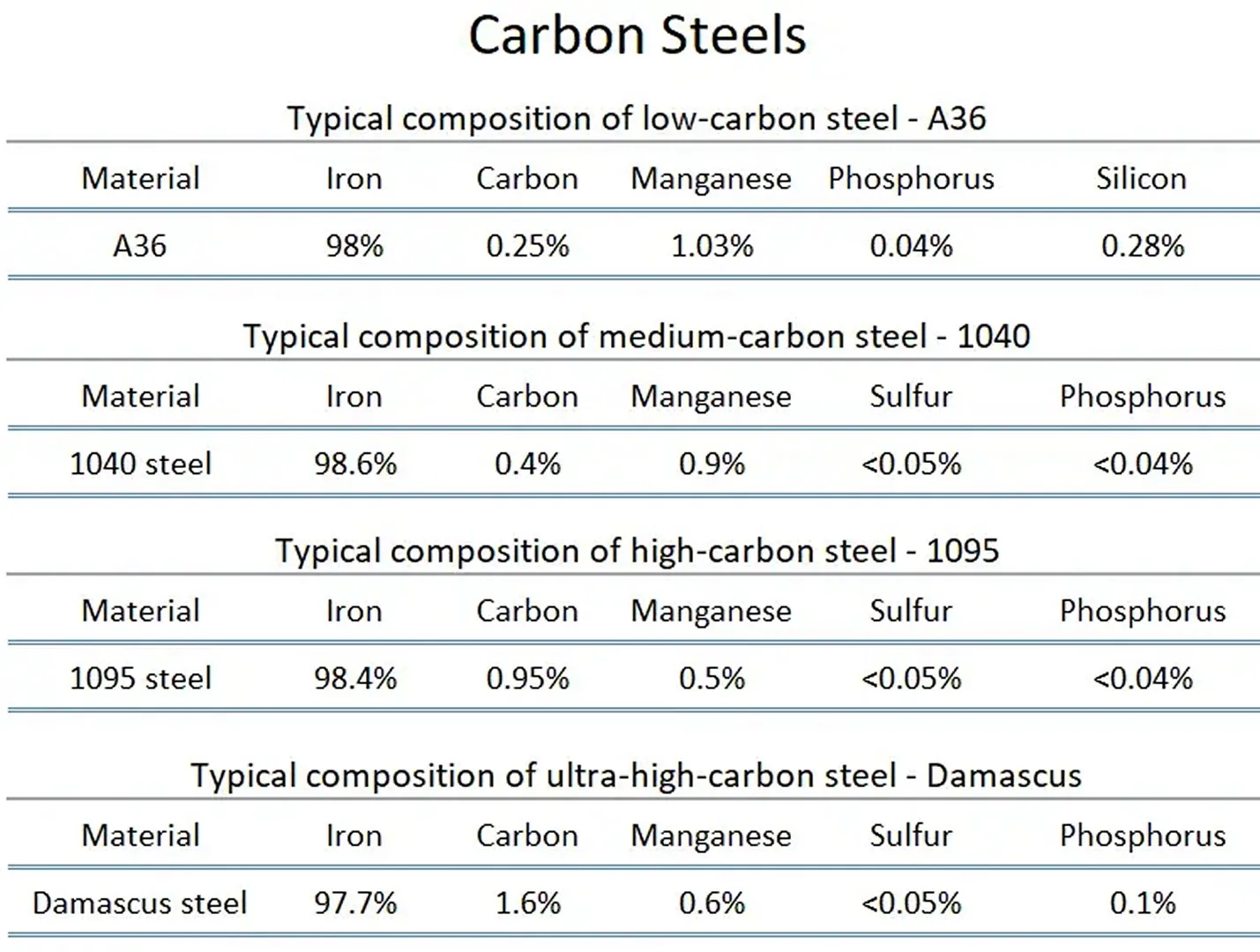

4. Carbon Steel

Carbon steel is a traditional material used in razor blade manufacturing. It is known for its exceptional sharpness and edge retention but requires careful maintenance to prevent corrosion.

Properties and Characteristics

- Exceptional sharpness

- High hardness and edge retention

- Prone to corrosion if not properly cared for

- Requires more skill to sharpen

Pros and Cons

Pros:

- Unparalleled sharpness and cutting performance

- Excellent edge retention for an extended period

- Preferred by experienced wet shavers who prioritize sharpness

Cons:

- Susceptible to corrosion without proper drying and maintenance

- Requires more expertise to maintain and sharpen

Comparing the Blade Materials

When choosing a double edge razor blade, it’s crucial to consider the following factors:

Durability and Sharpness

- 4cr13 and 6cr13 stainless steel offer a good balance between durability and sharpness.

- Swedish stainless steel provides exceptional durability and sharpness.

- Carbon steel offers unparalleled sharpness but requires careful maintenance to prevent corrosion.

Corrosion Resistance

- 4cr13 stainless steel provides moderate corrosion resistance.

- 6cr13 stainless steel offers improved corrosion resistance compared to 4cr13.

- Swedish stainless steel provides excellent corrosion resistance.

- Carbon steel is prone to corrosion if not adequately cared for.

Maintenance and Care

- Stainless steel blades are relatively easier to maintain compared to carbon steel.

- Carbon steel blades require diligent drying and occasional oiling to prevent corrosion.

| Material | Durability | Sharpness | Corrosion Resistance | Maintenance | Cost |

|---|---|---|---|---|---|

| 4cr13 Stainless Steel | Moderate | Moderate | Moderate | Easy | Low |

| 6cr13 Stainless Steel | Good | Good | Improved | Easy | Low |

| Swedish Stainless Steel | High | High | Excellent | Difficult | High |

| Carbon Steel | High | High | Needs Care | Difficult | High |

Conclusion

In conclusion, choosing the right material for your double edge razor blade is essential to achieve a comfortable and efficient shave. The four materials discussed - 4cr13 stainless steel, 6cr13 stainless steel, Swedish stainless steel, and carbon steel - each have their own unique characteristics and advantages. Consider factors such as corrosion resistance, durability, and maintenance requirements when selecting the perfect razor blade for your needs.

About Xirui Manufacturing

Xirui Manufacturing is a professional manufacturer and supplier of double-edged razor blades. We specialize in providing high-quality razor blades for wet shaving enthusiasts and professional barbers alike. Our products are made with precision and care, ensuring a comfortable and efficient shave every time.

We offer a wide range of razor blade materials, including 4cr13 stainless steel, 6cr13 stainless steel, Swedish stainless steel, and carbon steel. Whether you’re looking for a budget-friendly option or a premium-quality blade, we have something to suit your needs.

Please feel free to connect with us if you need to wholesale or customize double edge blades. We are always happy to help.

FAQs

- What materials are commonly used for double-edge razor blades? Double-edge razor blades are commonly made of stainless steel due to its corrosion resistance. Other materials include carbon steel and coated steel.

- How often should I replace my razor blade inventory? The frequency of blade changes depends on various factors, such as the material of the razor blade. As a general guideline, it’s recommended to replace the blade inventory every 3-6 months or when you notice a decline in performance.

- Can carbon steel razor blades be purchased in bulk? Yes, carbon steel razor blades can be purchased in bulk. However, they require diligent maintenance and care to prevent corrosion and ensure longevity.

- Which materials are recommended for bulk purchasing? For bulk purchasing, stainless steel blades like 4cr13 or 6cr13 are good options. They offer a balance between sharpness and durability, making them suitable for most customers.

- How do Swedish stainless steel blades compare to other materials for bulk purchasing? Swedish stainless steel blades are considered top-tier in terms of quality and performance. While they do come at a higher cost, they provide excellent corrosion resistance and long-lasting sharpness, making them a worthwhile investment for customers seeking premium quality.