How Safety Razor Are Made

The History of The Razor Blade

Since primitive times, shaving has been an important cultural grooming practice. Cave painting show that even the prehistoric men practiced shaving by scraping hair off with crude implements such as stones, flint, clam shells, and other sharpened natural objects. With the advent of the Bronze Age, humans developed the ability forge simple metals and began to make razors from iron, bronze, and even gold.

In 1762, a Frenchman named Jean-Jacques Perret invented the first ever safety razor. Modelled on a joiner’s plane, Perret’s design covered the blade on three sides to protect the user from nicks and cuts – very much in the same mould as today’s razors.

Until the nineteenth century, the most common razor was still a long handled open blade called a “cut-throat” razor which was difficult to use, required repeated sharpening, and was usually wielded by professional barbers.

Shaving practices began to change dramatically around the turn of the century. In 1895, an American named King Camp Gillette had the idea of marketing a disposable blade that didn’t require sharpening. Gillette designed a razor that had a separate handle and clamp unit that allowed the user to easily replace the blade when it became dull.This is a milestone in the history of the razor blade.

The Manufacturing Process of Safety Blade

Scraper Blades Manufacturing Processes in Xirui Blade Manufacturing Factory

Material Safety blades are periodically exposed to high levels of moisture and therefore must be made from a special corrosion resistant steel alloy. Furthermore, the grade of steel must be hard enough to allow the blade to hold its shape, yet malleable enough to allow it to be processed. The preferred type of steel is called carbide steel because it is made using a tungsten-carbon compound. One patented combination of elements used in stainless steel blade construction includes carbon (0.45-0.55%), silicon (0.4-1%); manganese (0.5-1.0%); chromium (12-14%) and molybdenum (1.0-1.6%); with the remainder being iron.

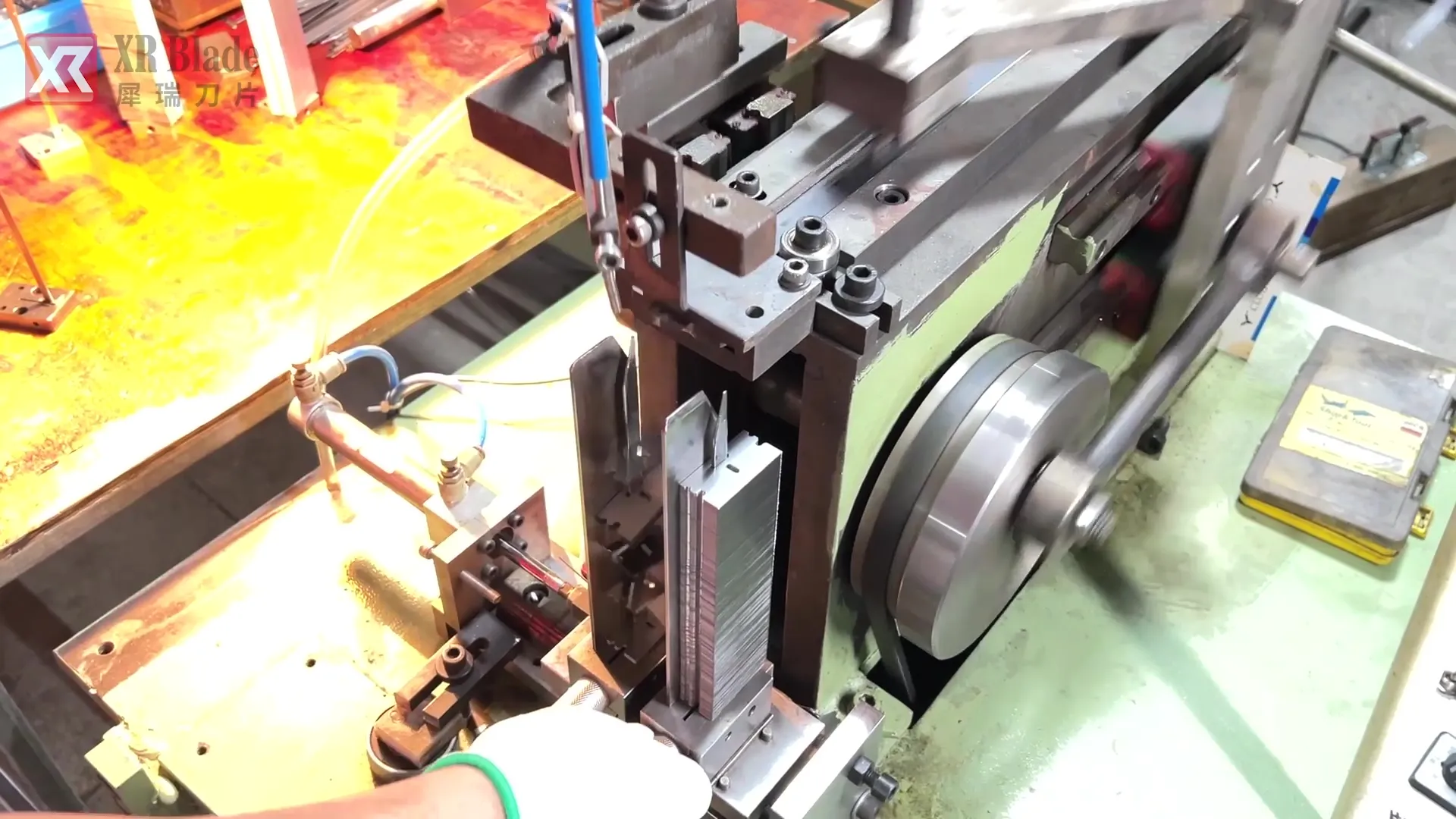

Punching Firstly the long steel belt is put a through a high speed machine.The blades are then die stamped at a rate of 800-1,200 strokes a minute to form the appropriate cutting edge shape. The actual cutting edge of modern cartridge style razor blade is deceptively small. The entire cutting surface is only about 1.5 in (3.81cm) wide by 1 mm deep.

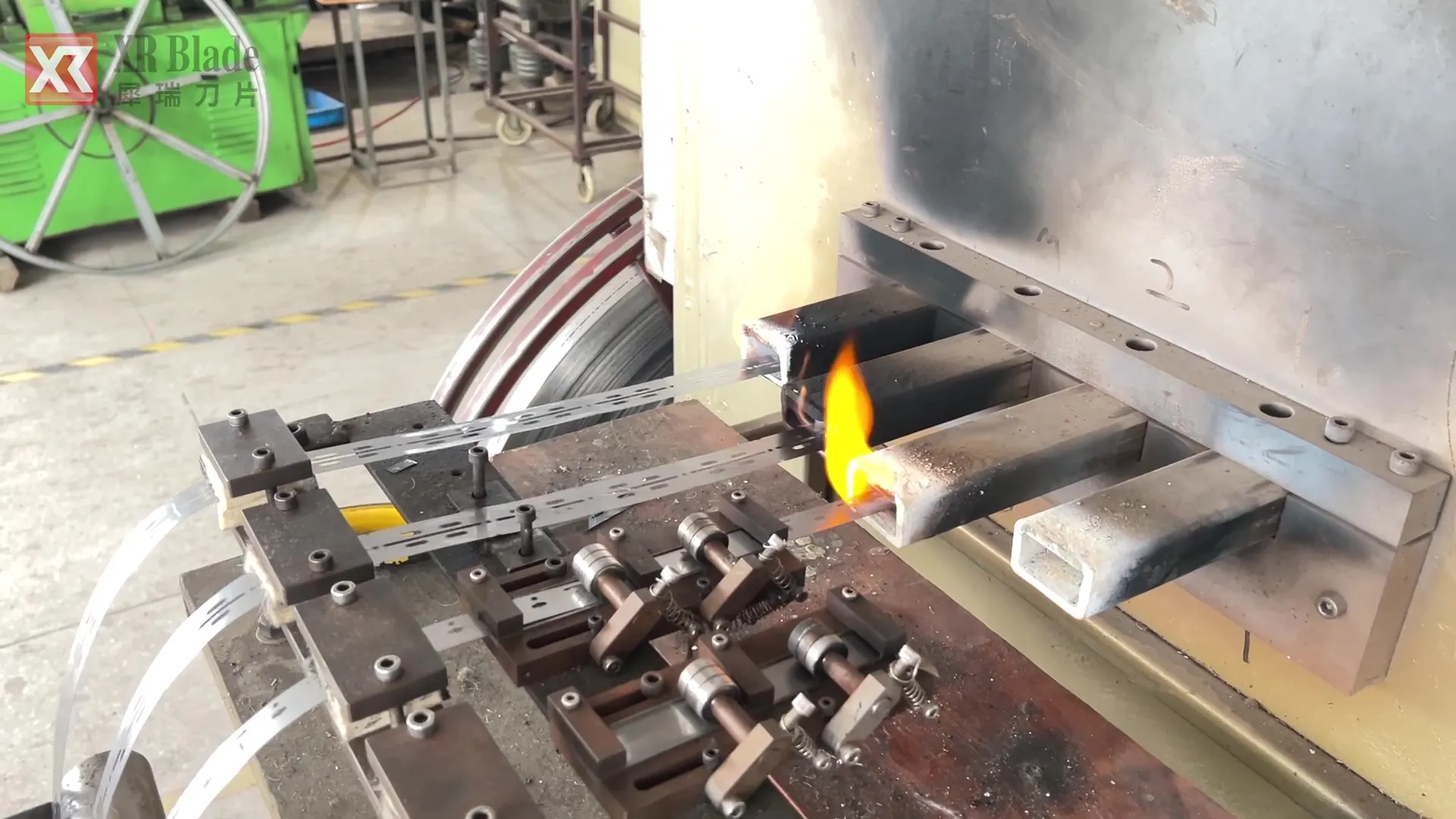

Heat Treatment The steel blade is heated to temperatures of

1,075°C - 1,120°C, then quickly cooled to between -60°C and -80°C to harden it, before being tempered again to a temperature of250°C - 400°C. This process is called ‘stressing out’ and is done to harden the metal without it becoming brittle.

Grinding and Polishing Once the product has reached the optimal hardness, it is then sent through a series of grinding and polishing machines. The purpose of the grinding machine is to sharpen the edges while the polishing machine cleans up the edges by removing any imperfections. Both the grinding and polishing procedures are incredibly important. Grinding the edges is what makes the edges sharp so it will cut the hairs right off. The polishing step smooths out the edges by removing any burrs or stray fragments from the cutting edges. DE blades need to have sharp but smooth edges to ensure they can cut the hairs without cutting the skin. One feature without the other renders a blade unusable and possibly dangerous.

Quality Control All finished razor components must conform to tight specifications before they are released. For example, blades must meet a designated hardness rating and contain a certain amount of steel.The sharpness of the blade must meet the standard.

Coating The first coating applied is typically a chromium based coating. It is applied to the entire blade but is intended to ensure that the cutting edges stay hard and resistant. Next, a non-stick coating is sprayed on. The last thing you want is for the blade to cause a lot of friction, you want the blade to just glide across your face. The non-stick coating helps reduce the amount of friction between your face and the blade which helps prevent skin irritation and razor burn.

Sintering A protective coating is bonded to the cutting edge in a process called ‘sintering’.

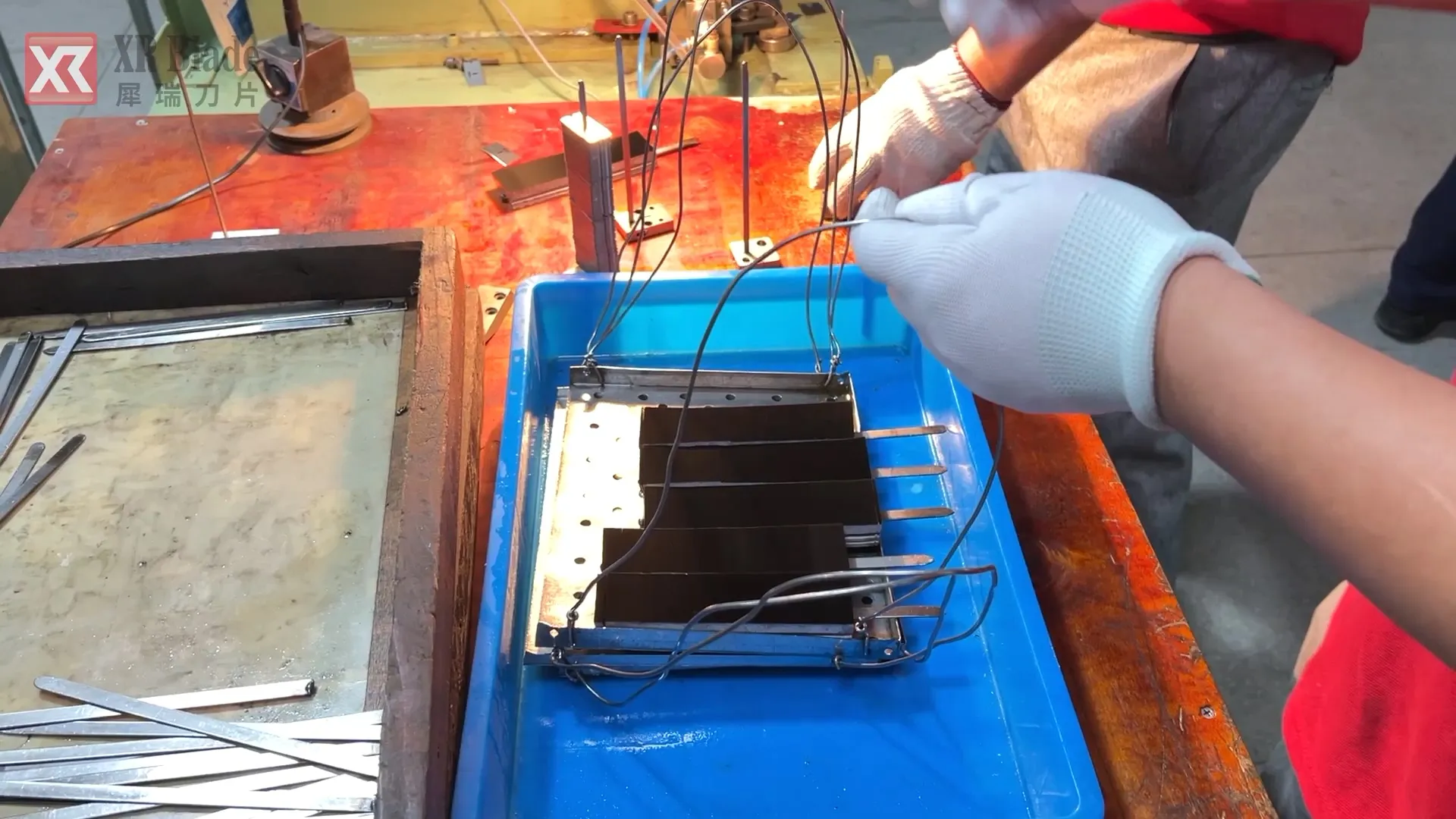

Soaking Oil-based Solution Lastly, the blades are submerged into an oil-based solution that helps give it some added protection from corrosion. Corrosion is the primary contributor to blade deterioration. Blades typically only last 4 or 5 shaves, but any added protection from blade corrosion is always helpful.

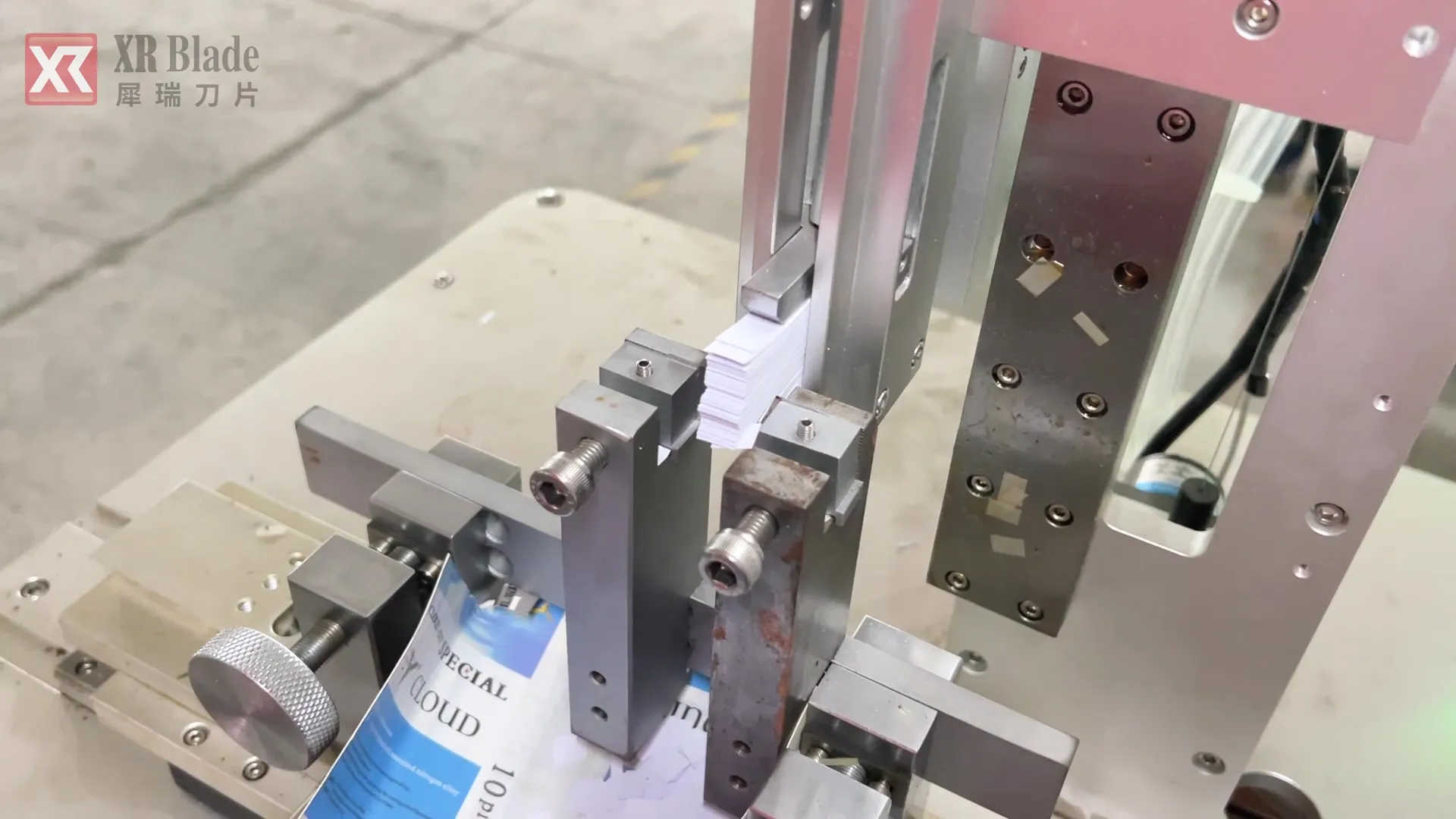

Packaging The edging part of the safety blade is usually wrapped in paper to prevent it from damaging itself as well as hurting others. The individual blades are then placed in plastic bags, plastic boxes or cartons and boxed by workers for storage.

Storage Packed blades are stored in the warehouse until they are sent to the customer.

Overall, the process of making a safety razor involves a combination of design and planning, cutting, press and shaping, edging and polishing, assembly and testing, and packaging and distribution. This multi-step process ensures that each safety razor is made to the highest quality standards and is ready to use when it reaches the consumer.

The process of blade production is one of continuous progress. As a blade manufacturer, we are constantly working on designing new and improved production systems and developing new manufacturing equipment. We will produce better quality blades to optimize the user experience.

If you would like to learn more about the production process of safety blades, you can click on the link below to watch a video about the production process of safety blades. You are also welcome to visit our factory in China to get up close and personal with blade production.